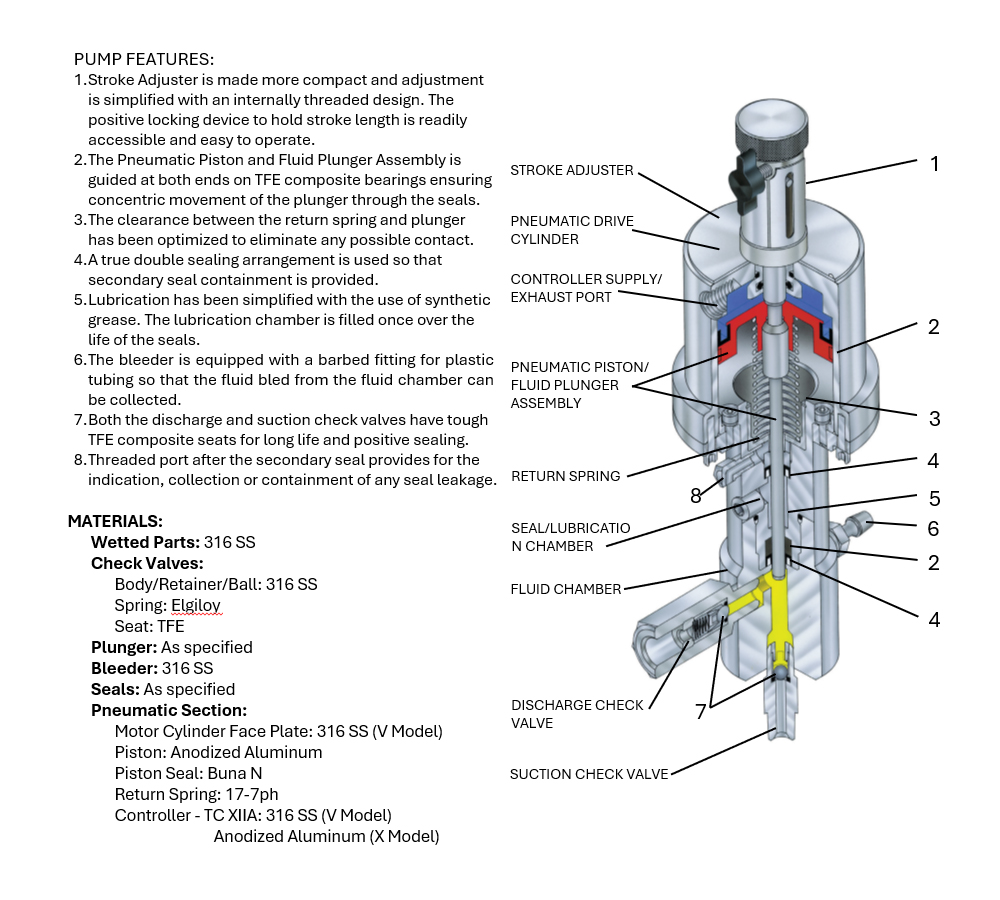

OPERATING CYCLE

POWER STROKE: As the CONTROLLER air or gas enters the PNEUMATIC DRIVE CYLINDER, the PISTON-PLUNGER ASSEMBLY is driven down into the FLUID CHAMBER, displacing fluid and compressing the RETURN SPRING. As the plunger displaces the fluid, the rise in pressure closes the SUCTION CHECK VALVE and opens the DISCHARGE CHECK VALVE. A precise amount of fluid, corresponding to the stroke of the plunger, is discharged.

SUCTION STROKE: When the air or gas is exhausted from the PNEUMATIC DRIVE CYLINDER the RETURN SPRING forces the PISTON-PLUNGER ASSEMBLY to return to its original position. The drop in pressure in the FLUID CHAMBER caused by the retraction of the piston allows the spring loaded DISCHARGE CHECK VALVE to close and the SUCTION CHECK VALVE to open so that the FLUID CHAMBER is again filled and ready for the power stroke.

MODEL @AIR/GAS SUPPLY PRESSURE | MAX VOLUME GPH/LPH | VOLUME PRE STROKE CC | STROKE LENGTH INCH | STROKES PER MINUTE (RANGE) | MAX DISCHARGE PRESSURE PSIG / BARG | MAX AIR CONSUMPTION | |

100 PSIG | 6.9 BAR | ||||||

SCF PER DAY | SCF PER DAY | ||||||

DSP 1/8V5/4 @100PSI/6.9BAR | .7/.27 | .1 | .5 | 1-45 | 8650 / 596.4 | 180 | 5 |

DSP 1/4V9/4 @100PSI/6.9BAR | .57/2.16 | .8 | 1 | 1-45 | 7200 / 496.4 | 1150 | 32 |

DSP 1/4V3 @100PSI/6.9BAR | .57/2.16 | .8 | 1 | 1-45 | 13,100 / 903.2 | 2100 | 59 |

DSP 1/2V9/4 @100PSI/6.9BAR | 2.30/8.71 | 3.2 | 1 | 1-45 | 1750 / 120.7 | 1150 | 32 |

DSP 1/2V3 @100PSI/6.9BAR | 2.30/8.71 | 3.2 | 1 | 1-45 | 3250 / 224.1 | 2100 | 59 |

DSP 1/2V4 @100PSI/6.9BAR @ 150 PSI/10.3 BAR | 2.30/8.71 2.30/8.71 | 3.2 3.2 | 1 1 | 1-45 1-45 | 6300 / 434.4 9200 / 634.3 | 3584 | 101 |

DSP 3/4V4 @100PSI/6.9BAR @ 150 PSI/10.3 BAR | 5.00/1.89 5.00/1.89 | 7.0 7.0 | 1 1 | 1-45 1-45 | 2600 / 178.3 4000 / 275.8 | 3584 | 101 |

DSP 3/4V4 @100PSI/6.9BAR @ 150 PSI/10.3 BAR | 9.08/34.37 9.08/34.37 | 12.7 12.7 | 1 1 | 1-45 1-45 | 1520 / 104.8 2300 / 158.6 | 3584 | 101 |

DSP 1V6 @100PSI/6.9BAR @ 150 PSI/10.3 BAR | 9.04/34.22 7.00/26.50 | 12.6 9.8 | 1 1 | 1-45 1-35 | 3400 / 234.4 4700 / 324.0 | 7190 | 203 |

DSRP 1V8 @100PSI/6.9BAR @ 150 PSI/10.3 BAR | 8.81/33.35 6.82/25.81 | 12.3 9.5 | 1 1 | 1-45 1-35 | 6300 / 434.4 9100 / 627.4 | 12342 | 349 |

This data should only be used to provide you with your initial size selection. You must refer to the actual performance graphs on pages 6 and 7 in order to verify your pump selection.

PLUNGER PUMP SELECTION GUIDELINE

PLEASE NOTE: OUR PLUNGER PUMPS HAVE PRESSURE-ACTIVATED SEALS. THEY SHOULD BE USED AT PRESSURES WHICH MATCH THE SEAL SELECTION

STROKE RATE AND LENGTH

Even though the pumps are designed to operate over their entire stroke rate and length ranges, we suggest that you take into consideration your future flow requirements. Rather than operating at the flow extremes you may wish to use the next pump size larger or smaller.

FILTRATION

Plunger pumps are susceptible to contamination. Therefore we recommend a 25 micron filter in the suction line of the pump.

SUCTION CONDITIONS

The V Series plunger pumps are designed for flooded suction only. They are NOT recommended for a suction lift condition. The recommended pressure at the suction inlet is:

1 ft. (.3 meters) min. • 10 ft. (3 meters) max.

NOTE: The normal cracking pressure of the discharge check valve is 90 PSI.

VISCOSITY

The maximum recommended viscosity is 4500 SSU (Saybolt Seconds Universal) or 960 CP (Centipoise).

FLOW TURNDOWN RATIO: 100:1

NOTE: The flow turndown ratio is defined as the total flow range of the pump, which includes both speed and stroke length adjustments.

ACCURACY

± 0.5% with Solenoid Valve

± 0.5% with TC-XII Controller

TEMPERATURE

The seals are the limiting factor. Please refer to the seal selection guide for temperature limits.

AIR/GAS SUPPLY

The air/gas supply must always be regulated since fluctuating pressures will affect speed and accuracy. The air/gas must be free from particulate and we recommend dry air/gas for trouble free operation.

PUMP SETTING GAUGE

We recommend the use of a pump setting gauge as a simple method of adjusting the flow of the pump.

DISCHARGE LINE CHECK VALVE

It is good design practice to install a check valve in the pump discharge line at the point it enters the process line. This will prevent the process fluid from reaching the pump.

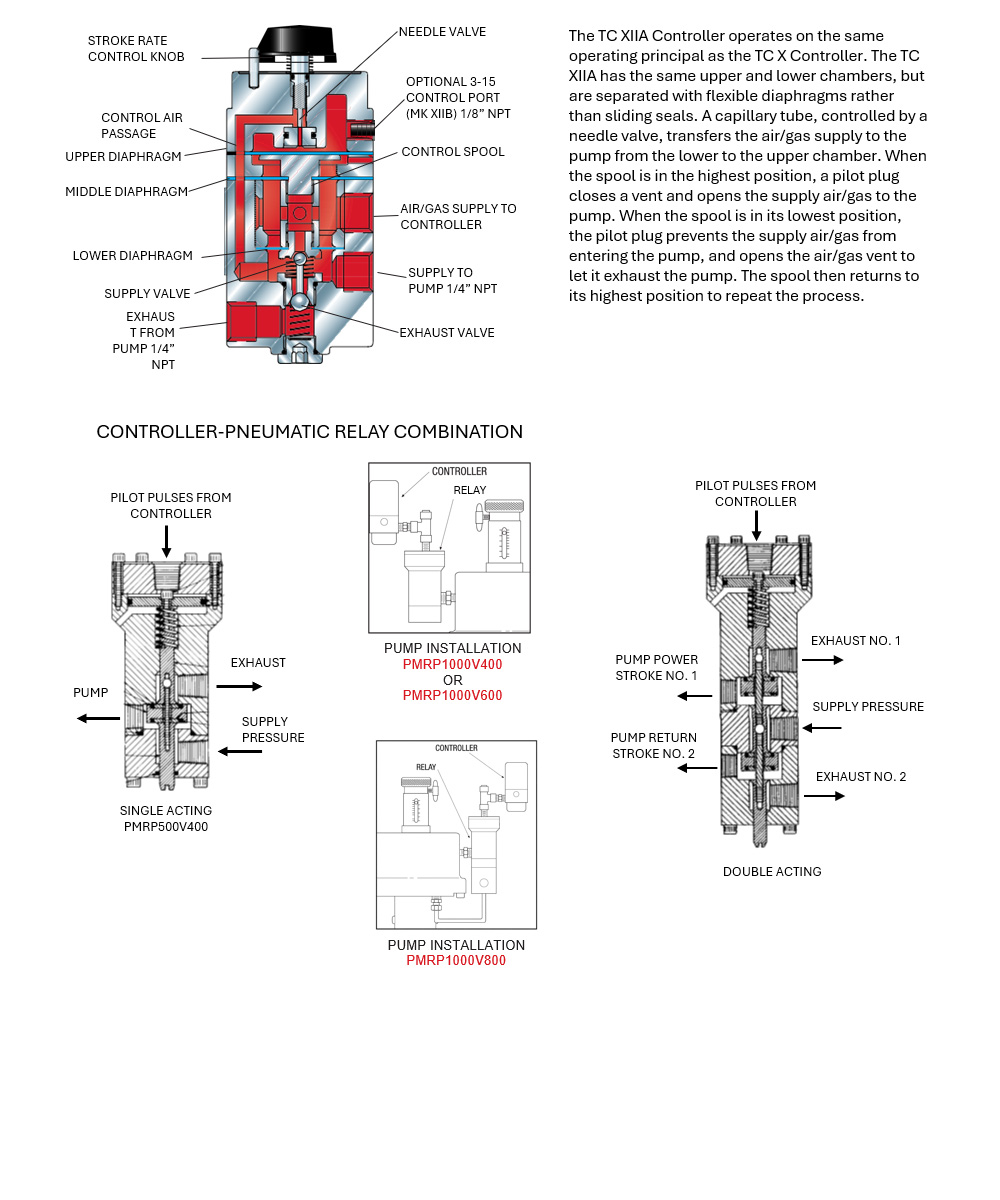

The PNEUMATIC RELAY is a pilot operated valve designed to provide the higher air or gas flow rates necessary for PNEUMATIC DRIVE CYLINDER diameters greater than 3 inches. The PNEUMATIC RELAY is actuated by the pulses produced by the TC-XII OSCILLAMATIC® CONTROLLER. A single acting PNEUMATIC RELAY is used with pumps that have return springs such as the PMRP1000V400 and PMRP1000V600. The air or gas pressure is required to return the PISTON-PLUNGER ASSEMBLY on the PMRP1000V800. Therefore a double acting PNEUMATIC RELAY is required.